|

RF Design-Course Development |

1 Course description as initially planned

The course will emphasize the experimental laboratory component.

50% of class meetings will be held in the electronics labs in

the form of a studio. The class of 25 students will be divided into four

teams of 6±1 students.

The RF Design course can be best described by the following scenario:

For the first class meeting, four cardboard boxes will be brought to

class, each containing various electronic modules. There will be one box

for each team to use during the semester.

Each box contains about 30 modules which (if connected together)

function as a Gigaherz-range transmitter/receiver (two-way radio). Each

team member is given 5 modules for the duration of the semester. The

modules are labeled and specified such that it is clear what kind of

function they perform. However, the details of their design are unknown

(the board can be painted over to hide the layout).

The goal of each student will be to design and build the equivalents of

the five modules. Each student is individually responsible for

designing and building his modules. But also, the modules are parts of

the entire communications system. The whole team must work together on

the entire system to clarify the input/output dependencies between the

modules. The grade for each student will depend both on the individual

work and collaborative work in certain percentages (to be established).

The main advantage of the proposed approach to teaching the RF design is

that from the beginning of the semester each team has a working radio to

experiment with. Students can learn about individual modules, measure

them and draw conclusions from the live hardware. It will be up to the

students to decide what kind of knowledge they need to learn to be able

to design and build the modules. After the semester is over, the

students will have five circuits each to present to their prospective

employers during the job interview.

2 Participants

A group of people is involved in developing the RF Design class:

(send group email)

3 Weekly meetings

1/12/2004

Fist, we talked about the structure of the system that we are going to

build. There will be two antennas made of cans, and there will be two

circuits; one for transmitter and one for receiver. The system will

work at 2.4GHz frequency. Pringles cans are suitable for this frequency.

The bandwidth will be around 100 MHz, suitable for the standard Ethernet

signal.

There will be modules like filters, VCO's and frequency converters in

the transmitter and receiver. Transmitter circuit will have to deliver

enough power for the receiver in given conditions.

There will be around 30 modules in two circuits. Everyone in the group

will be responsible for 5 of them. Everyone should build one module

every three week. PCB will be used for building every module. We might

use a chemistry lab because there will be lots of etching. The circuit

will be made up from PCB boards connected to each other directly or by

coaxial cables. We are planning to put the modules chip enclosures.

Before the modules are built, we will use function generator and

spectrum analyzer to find out the gain and noise properties of the

antennas.

The RA will be responsible for learning how to use the equipment. All

the materials and manuals will be given to the RA, and they will be

posted on web. All the meeting reports will be posted on web.

There will be meetings on Mondays from 04:30p to 05:30p

On the next meeting:

The way to build the inductance, which will be used in VCO, will be

ready. What to do first and next will be discussed. The properties of

the antennas will be discussed. So that some of the properties of the

modules will be found.

1/19/2004

Andy will work on selecting the oscillator circuit for the VCO.

Steve will use the inside of an old HP sweeping generator to produce an

AM modulated signal in the GHZ range. Ultimately this will become a

project on the AM modulator for the transceiver.

Open question: how much power do we need in the transmitting antenna to

be able to go through two leyers of standard shingles of a typical

house. This would enable placing the system at the attics.

1/26/2004

Alper figured out how to properly calibrate the network analyzer. It

turns out that the improvised terminations and vias are sufficient to

calibrate the analyzer - no Agilent kit will be necessary. The overall

goal is to build things cheaply and from scratch.

Sasi will review approaches to build the amplifier with

impedance-matched input and output. Several stages of such amplifier

will be used in various places in the transceiver circuit.

Dave is studying Ansoft simulators to master such skills and create some

documentation on the software use for future students to use. Ansoft

Designer has too many features disabled in the student version to be

really useful. We will go with Serenade which has the harmonic balance

enabled.

We bought some parts:

Quantity Digikey code

20 BFP405INCT-ND RF transistor, case SOT-343, price 0.5800

20 NE85634CT-ND RF transistor, case SOT-89, price 0.9000

16 MA2S37700LCT-ND varicap diode, case SS-mini, price 0.4400

10 MA2SV0200LCT-ND varicap diode, case SS-mini, price 0.4300

2/02/2004

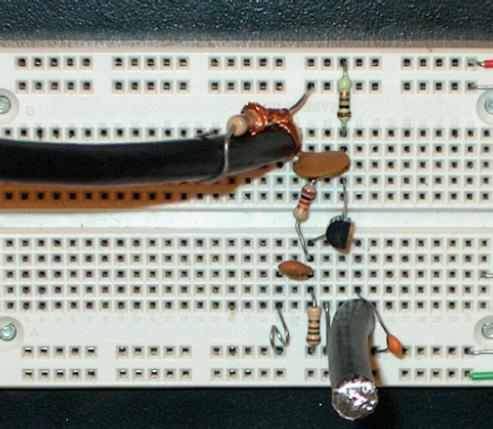

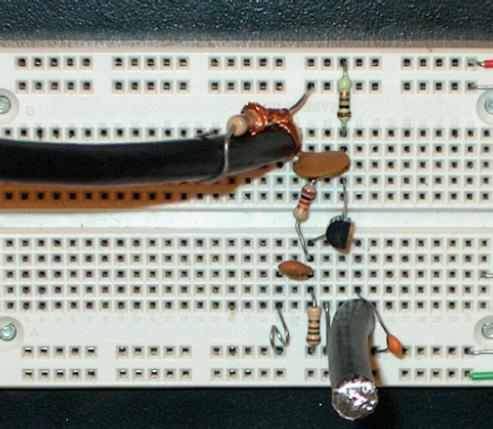

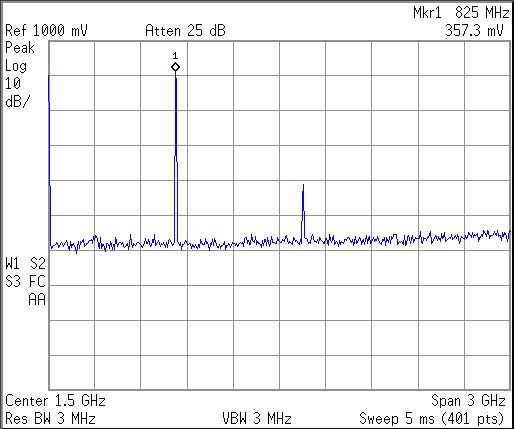

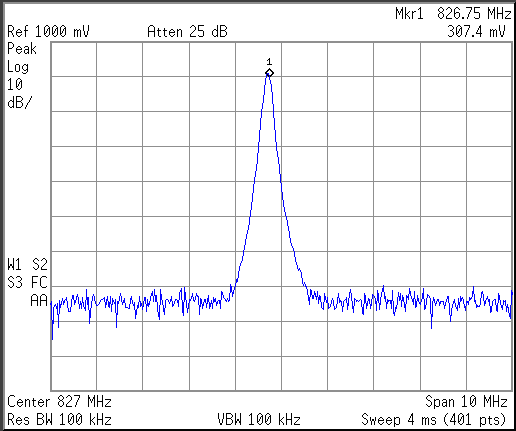

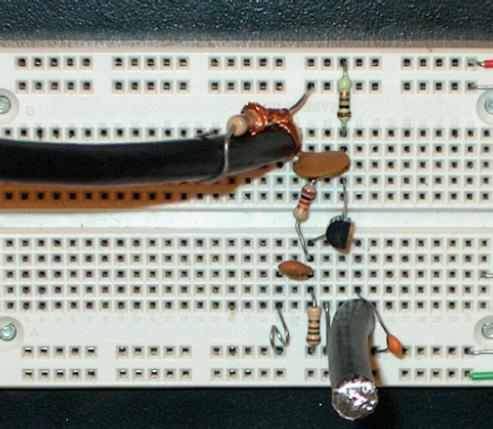

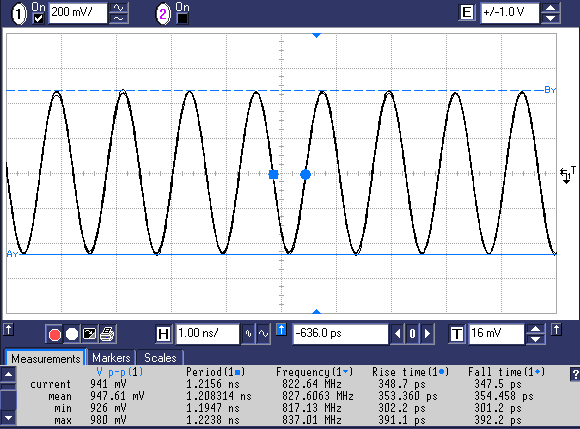

While waiting for the parts to come, Andy used the 2N 5770 to construct

an oscillator and maximize the frequency of oscillations. The result is

shown in Fig. 1. Not bad at all for the breadbord! The

actual design should be easier, since the BFT405 has ft=25GHz.

Figure 1: A 827MHz Hartley oscillator built using a transistor with

fT=1GHz in the common-base topology. The shorted stub functions

an inductor for the tank circuit in the emitter. Two turns of a

resistor lead makes up the base inductor.

Figure 1: A 827MHz Hartley oscillator built using a transistor with

fT=1GHz in the common-base topology. The shorted stub functions

an inductor for the tank circuit in the emitter. Two turns of a

resistor lead makes up the base inductor.

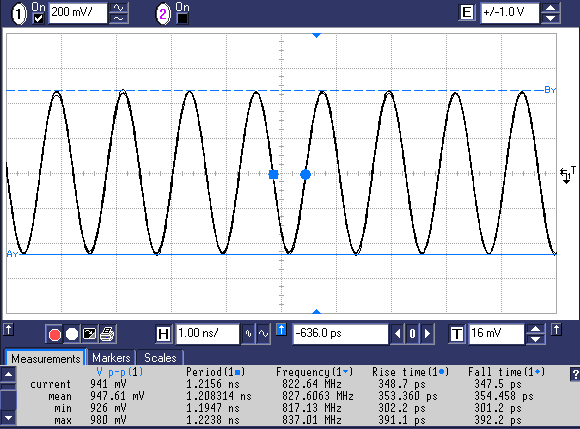

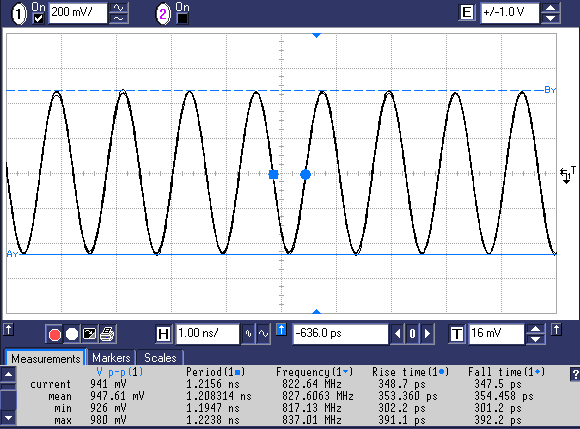

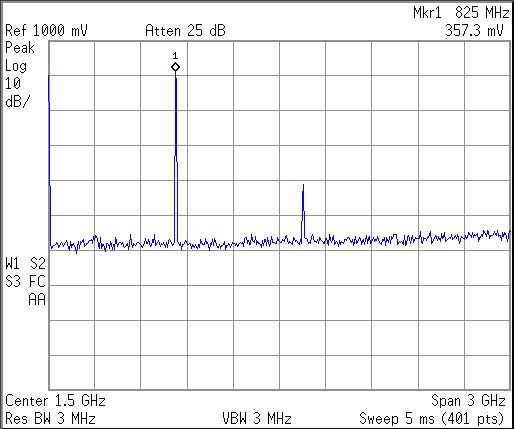

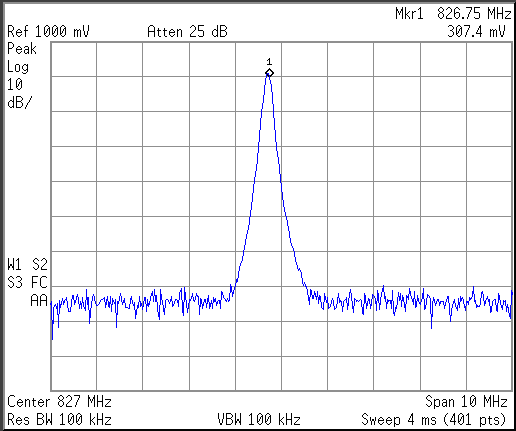

Figure 2: The spectrum of the 827MHz oscillator.

Sasi has preliminary design consideration on how to build the amplifier

for 50Ohm input and output and 2.4GHz.

Figure 2: The spectrum of the 827MHz oscillator.

Sasi has preliminary design consideration on how to build the amplifier

for 50Ohm input and output and 2.4GHz.

2/10/2004

We discovered that Pringle cans are coated with some plastic on the

inside so that the connector does not stick to it very well. Moreover

the sheet resistance of the metal foil used on the inside of the cans is

quite high. We decided to go with coffee cans instead, shown in

Fig. 3.

Figure 3: Coffee can antennas.

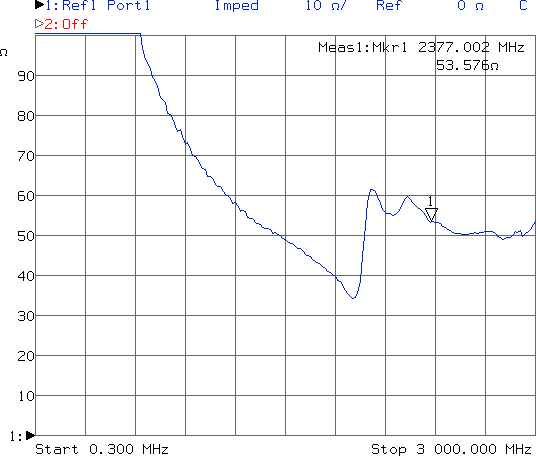

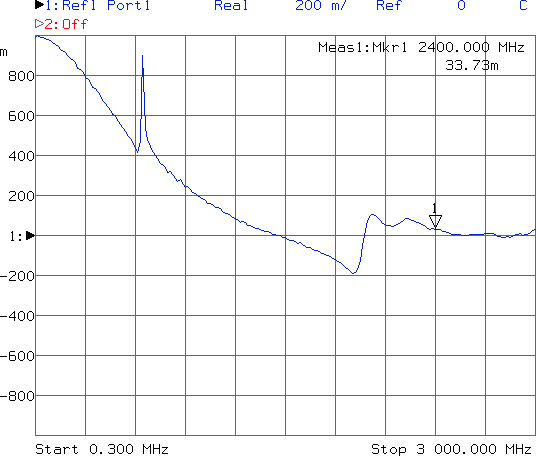

Alper made some initial measurements on the coffee can antenna with

the N-type connector made by Dustin.

Figure 3: Coffee can antennas.

Alper made some initial measurements on the coffee can antenna with

the N-type connector made by Dustin.

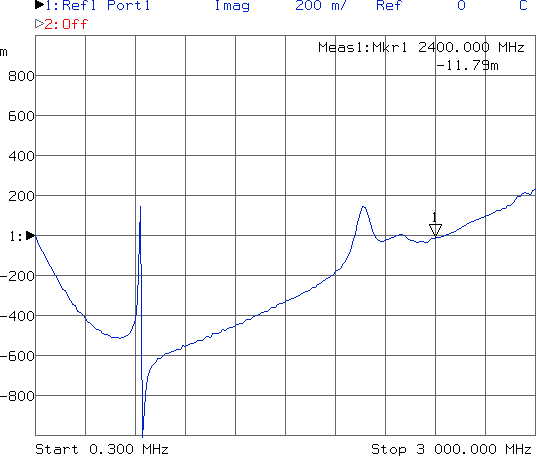

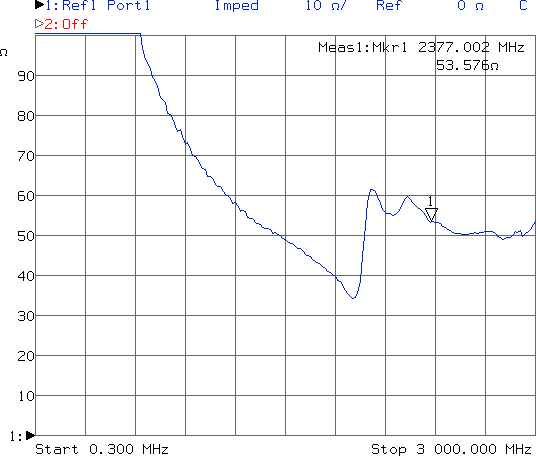

Figure 4: The coffee can antenna impedance sweep Z(f).

Figure 4: The coffee can antenna impedance sweep Z(f).

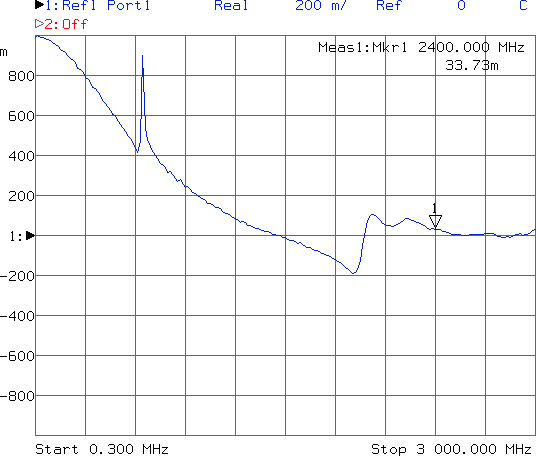

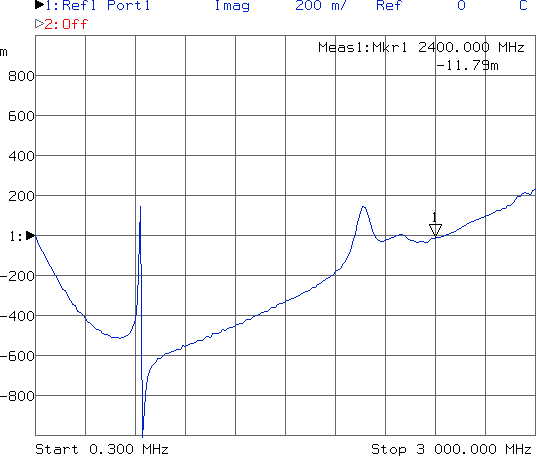

Figure 5: The coffee can antenna. Resistance R(f) (left) and reactance

X(f) (right) sweeps.

More measurements will be made and compared with additional can antennas

produced with the panel-mount BNC connectors.

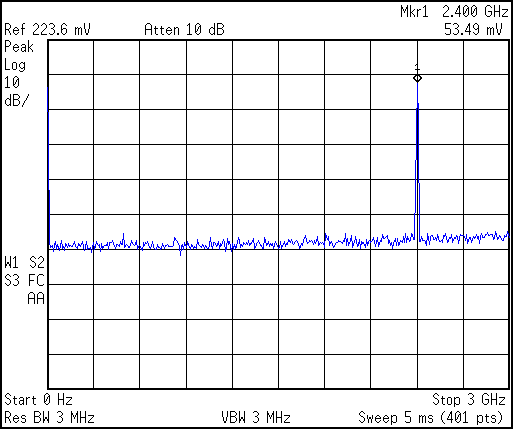

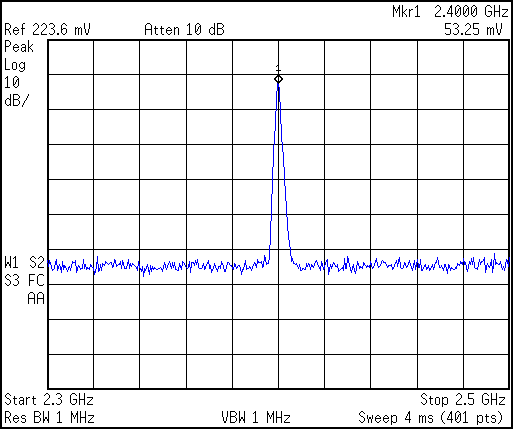

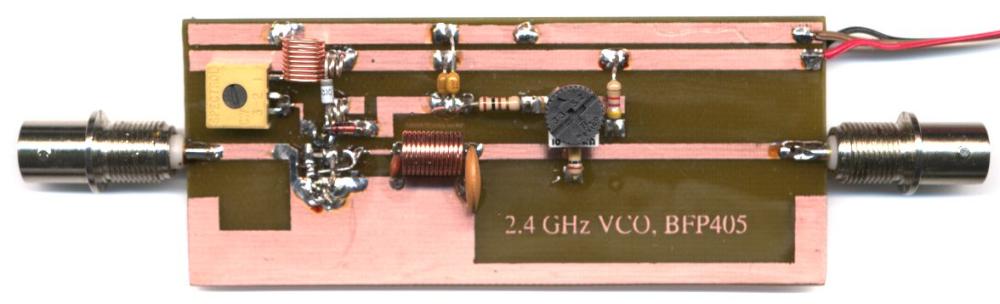

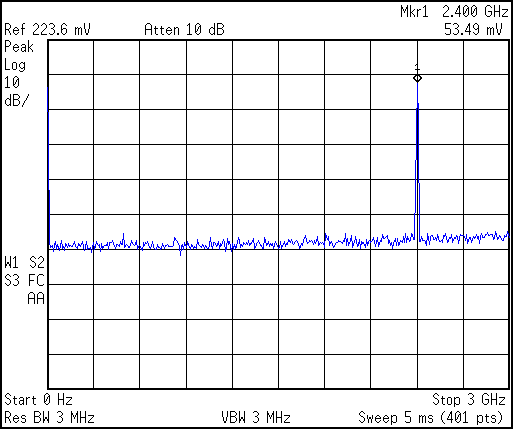

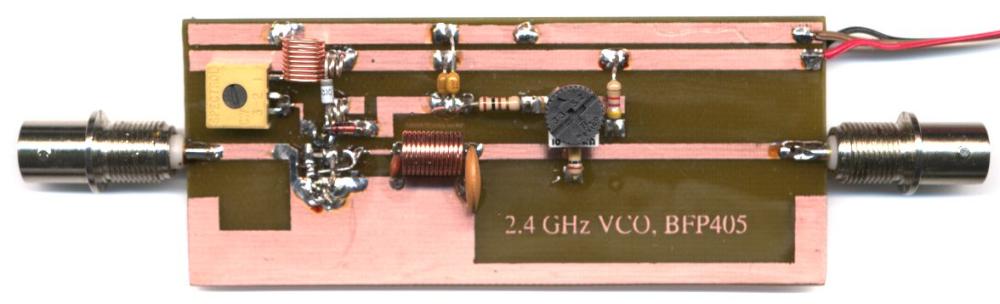

The VCO is finally working! The circuit is primarily the Colpitts

oscillator. It is build on a copper board with the microstrip inductor

and SMD transistor BFP 405, SMD varactors MA2S377, and SMD

capacitors, the rest of the parts are regular feed-through. The output

is only weakly connected to the tank circuit through 20dB

coupling. This makes the output very low, but the stability of the

oscillator is not compromised by the load.

Figure 5: The coffee can antenna. Resistance R(f) (left) and reactance

X(f) (right) sweeps.

More measurements will be made and compared with additional can antennas

produced with the panel-mount BNC connectors.

The VCO is finally working! The circuit is primarily the Colpitts

oscillator. It is build on a copper board with the microstrip inductor

and SMD transistor BFP 405, SMD varactors MA2S377, and SMD

capacitors, the rest of the parts are regular feed-through. The output

is only weakly connected to the tank circuit through 20dB

coupling. This makes the output very low, but the stability of the

oscillator is not compromised by the load.

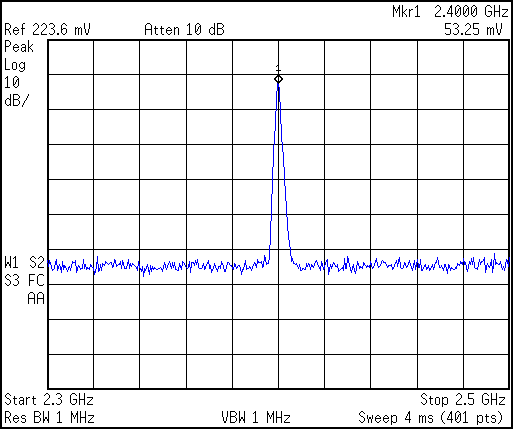

Figure 6: Spectrum of the 2.4GHz VCO.

Figure 6: Spectrum of the 2.4GHz VCO.

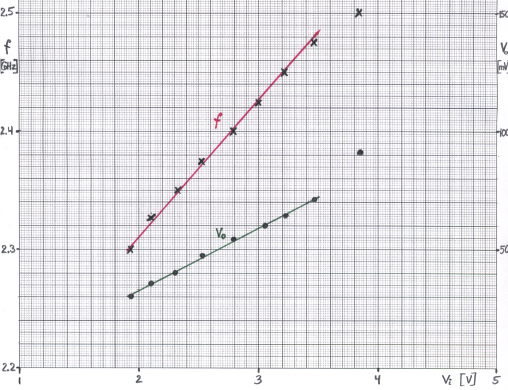

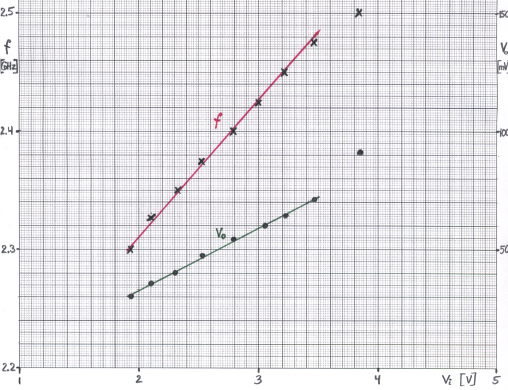

Figure 7: Characteristic of the VCO.

Figure 7: Characteristic of the VCO.

Figure 8: The VCO.

Enclosure from Lowes:

"Handy Box Welded", $1.07, Model #8650, Item #19849

Made by Hubbel Electrical Products and Raco

Dimensions 4"×2"×1[1/2]" deep.

Figure 8: The VCO.

Enclosure from Lowes:

"Handy Box Welded", $1.07, Model #8650, Item #19849

Made by Hubbel Electrical Products and Raco

Dimensions 4"×2"×1[1/2]" deep.

Figure 9: The VCO enclosed in the metal box.

Figure 9: The VCO enclosed in the metal box.

3/1/2004

Alper experimented more with can antennas. He was trying to determine if

there is an advantage of a longer antena over the shorter one. In

particular if a long antenna is more directional. There was no

signifficant improvement in the beam shape over the distance from one

work station to the other in the Electronics Lab. Therefore, for now we

will go with coffee cans then. They are easier to build than the long

antenna, shown in Fig. 10.

Figure 10: Long antenna made from sheet metal.

Figure 10: Long antenna made from sheet metal.

3/15/2004

We discussed various approaches to up- and downconvert the signal. The

final decission will be based on the properties of the signal to be

transmmitted. We plan on sending the standard 100bit/s Ethernet

signal. We were concerned if the DC is a necessary component of the

signal and how much of the low frequency component is required for

errorless operation of network cards.

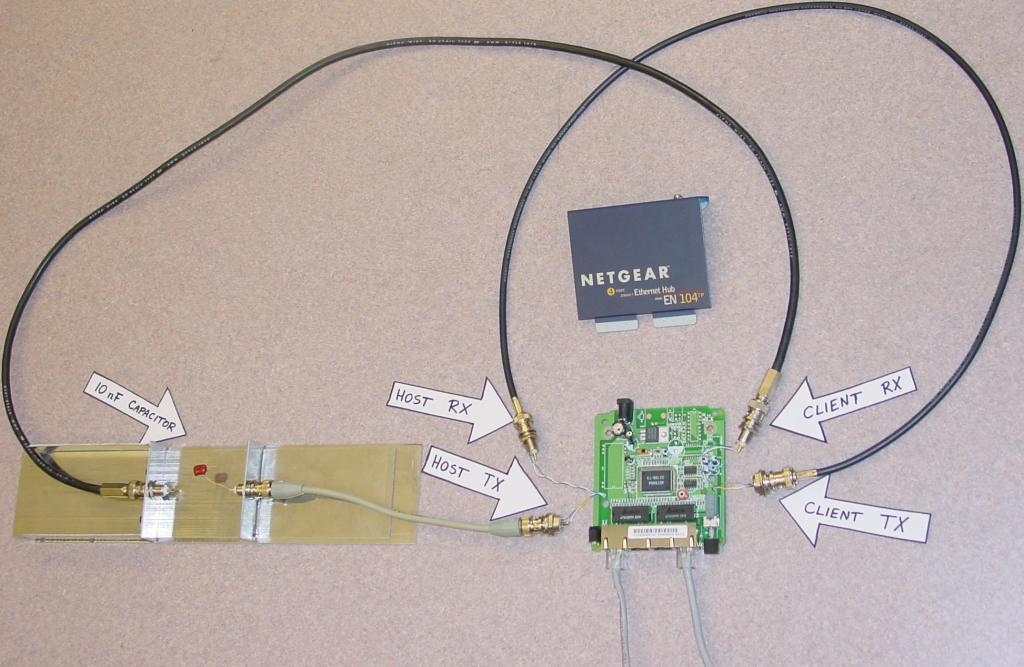

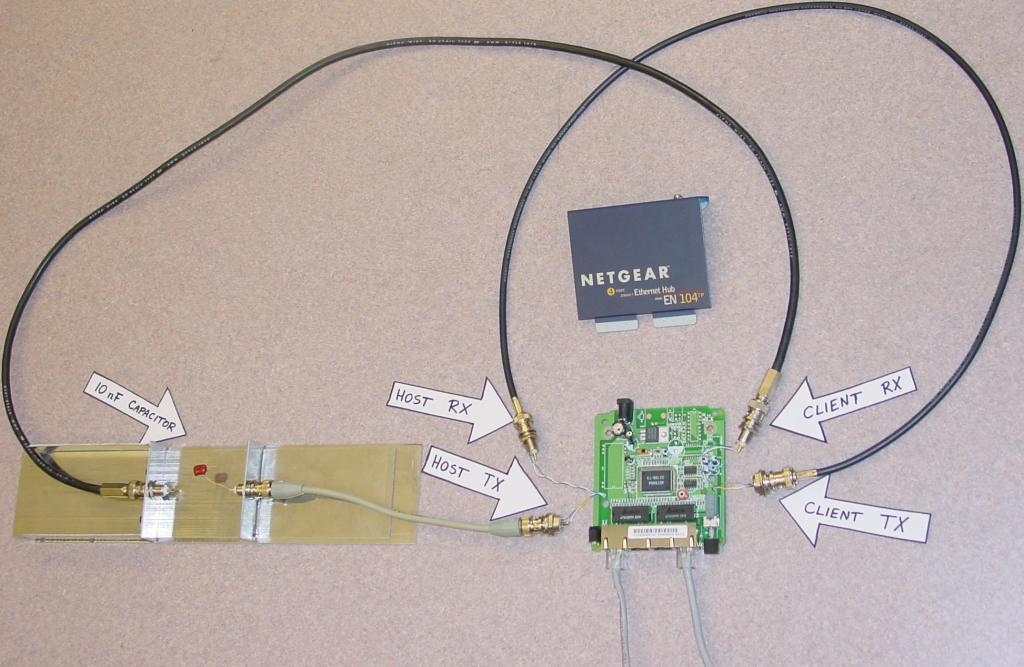

To investigate the baseband signal, Steve created a breakout box out of

an Ethernet hub. Each socket contains two twisted-pairs: the

transmitting pair TX and the receiveing pair RX. There are a few of the

sockets for clients and one socket for host (numbered as 1). Steve

tapped into two of these sockets to get the signals out of the

enclosure. We used standard coax cables to interconnect the TX-RX pairs

keeping the hub disconnected from its power supply. Also, we used a

capacitor to remove the DC from one of the signal paths. The lowest

capacitance value still enabling errorless Ethernet transmission was

10nF.

Figure 11: Ethernet hub made into a break-out box for testing signals.

None of the wires in the twisted pairs cannot be grounded. This means

that we will have to convert from differential to asymmetric signal

before we use it in further stages. For now the breaout box will be

modified to have four BNC connectors for host and four BNC connectors

for client - each wire spearately. We tested that as well.

Figure 11: Ethernet hub made into a break-out box for testing signals.

None of the wires in the twisted pairs cannot be grounded. This means

that we will have to convert from differential to asymmetric signal

before we use it in further stages. For now the breaout box will be

modified to have four BNC connectors for host and four BNC connectors

for client - each wire spearately. We tested that as well.

3/29/2004

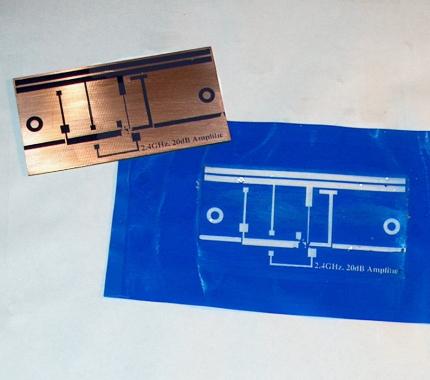

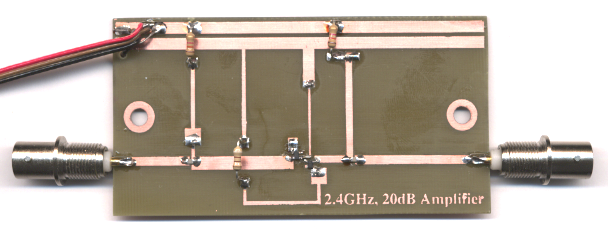

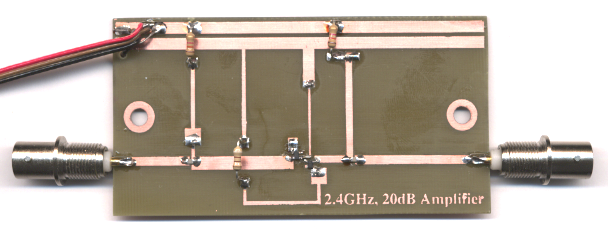

We are ready to build the high-gain amplifier for the carrier signal

produced by the VCO. The design is a cascode of common-base and

common-collector stages. Out of the three possible combinations, this

selection seemed to be the most stable and the closest to the optimal

impedance match. The BFP 405 transistors are used. We can count on at

least 20dB gain at 2.4GHz frequency.

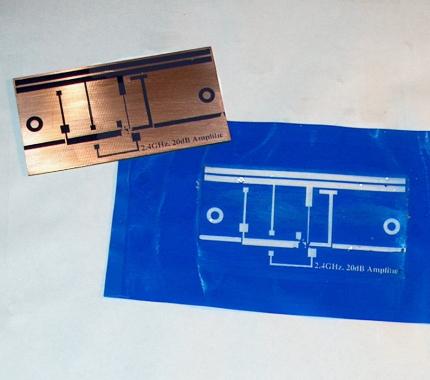

The circuit is fabricated using the product called Press-n-Peel PCB

Transfer Film. First, the circuit layout needs to be designed such that

it can be printed with exact geometries as specified by calculations and

simulations. We use 98mm × 50mm size board, because

it nicely fits in the metal enclosure. The raw double-sided copper board

has to be cut to size, as shown in Fig. 12. Using Brillo

pads, the board needs to be nicely cleaned on both sides so that the

copper surface has no evidence of fatty residum comming from our

fingers.

Figure 12: Fabrication of a double-sided printed circuit board

(PCB). Cleaning and layout transfering (left), transferred layout

(middle), etching (right).

The layout should be printed in reverse (mirror image) on the

Press-n-Peel blue sheet. It is a good idea to print multiple copies of the

layout on the same sheet in case we have to redo the process. As shown

in Fig. 12, one copy of the layout is cut from the sheet, the

copper board placed underneth it and everything is fixed together with

scotch tape.

The printer toner will transfer from the blue sheet to the copper board

when heated with the iron. Refering to the Press-n-Peel manual, the iron

should be set between acrylic and polyester setting. It takes less then

5 minutes of ironing to warm up the board so that the toner fully

detaches from the blue sheet. Unfortunately there is no way to tell when

the board is ready. After the heating time, the board and the sheet are

stuck together. The board can be cooled down under the cold water. The

sheet should be peeled off the board, as shown in

Fig. 12. There will be places with missing toner. Small

problems can be fixed with a permanent marker. Bigger missing patches

can be covered with the regular nail polish.

In case there are too many problems, it is generally better to start

over on the other side of the board. The iron temperature can be

readjusted according to the type of problem. If too hot, the toner melts

completely and distorts the layout. If too cold, the toner does not

transfer completely. It is a good idea to mark the optimum iron setting

for the future times.

When the transfered layout is in a satisfactory condition, the other

side of the board should be fully covered with the nail polish. The

other side will serve as a ground plane for microstrips. On the front

side, the unmasked copper will be etched out from the board in the

etching solution. In the figure, ferric chloride solution is used. If

the board is dropped flat on the solution surface it will float. This

promotes etching since there is no sediment settling on the board. Be

aware that ferric chloride permanently stains clothing. About twenty

minutes of time is sufficient to finish etching. The board should then be

washed in water and the nail polish and the toner should be removed with

the nail polish remover. The leftover toner can be further removed with

the Brillo pad.

Figure 12: Fabrication of a double-sided printed circuit board

(PCB). Cleaning and layout transfering (left), transferred layout

(middle), etching (right).

The layout should be printed in reverse (mirror image) on the

Press-n-Peel blue sheet. It is a good idea to print multiple copies of the

layout on the same sheet in case we have to redo the process. As shown

in Fig. 12, one copy of the layout is cut from the sheet, the

copper board placed underneth it and everything is fixed together with

scotch tape.

The printer toner will transfer from the blue sheet to the copper board

when heated with the iron. Refering to the Press-n-Peel manual, the iron

should be set between acrylic and polyester setting. It takes less then

5 minutes of ironing to warm up the board so that the toner fully

detaches from the blue sheet. Unfortunately there is no way to tell when

the board is ready. After the heating time, the board and the sheet are

stuck together. The board can be cooled down under the cold water. The

sheet should be peeled off the board, as shown in

Fig. 12. There will be places with missing toner. Small

problems can be fixed with a permanent marker. Bigger missing patches

can be covered with the regular nail polish.

In case there are too many problems, it is generally better to start

over on the other side of the board. The iron temperature can be

readjusted according to the type of problem. If too hot, the toner melts

completely and distorts the layout. If too cold, the toner does not

transfer completely. It is a good idea to mark the optimum iron setting

for the future times.

When the transfered layout is in a satisfactory condition, the other

side of the board should be fully covered with the nail polish. The

other side will serve as a ground plane for microstrips. On the front

side, the unmasked copper will be etched out from the board in the

etching solution. In the figure, ferric chloride solution is used. If

the board is dropped flat on the solution surface it will float. This

promotes etching since there is no sediment settling on the board. Be

aware that ferric chloride permanently stains clothing. About twenty

minutes of time is sufficient to finish etching. The board should then be

washed in water and the nail polish and the toner should be removed with

the nail polish remover. The leftover toner can be further removed with

the Brillo pad.

Figure 13: The amplifier.

Figure 13: The amplifier.

4 Strategy changes

4.1 Photo-litographic PCB development

After sever trials it became evident that the Press-n-Peel technology

does not provide enough accuracy on fine details of the PCB layout. It

is practically impossible to accomplish a good quality trace of the

width less than 0.5mm. A frequency mixer circuit has been

built. Fine trace separations between coupled lines could not be

accomplished. This resulted in unacceptable power loss beyond 40dB.

The team decided to abandon the Press-n-Peel approach and find a

simple way to arrange a photo-litographic PCB development

process. Ultra-violet exposure box and positive photo-resist substrate

material has been acquired to make new boards. Previously quite thick

boards were used. The decission was made to go with much thinner

boards. Most of the insertion loss in the circuits will be due to the

cheap FR4 dielectric material, not the copper resistivity. Therefore it

was reasonable to reduce the dielectric width trading it for the reduced

trace width. The new choice was the Injectorall 30mil board with 1 oz

copper. Thinner boards would be to fragile and easily break when dragged

across the table by the cables.

4.2 RF simulator: Ansoft Designer

It has been near impossible to effectively design RF circuits from

equations. Secondary effects are to signifficant to ignore in the

process of prototyping. There is no practical way to account for such

secondary effects without careful simulation. Initially, to avoid

problems, certain methods of circuit design were used such us placing

grounding capacitors inside a whole drilled through the board, or

placing the ground plane on the trace layer of the board. However, the

design process and circuit fabrication are tedious and

counter-productive. They are also questionable from the educational

perspective.

With the help of the School of Engineering Computer Committee who

provided funds, and Ansoft Corporation which offered tremendous

educational discount, the state-of-the art simpuation software Ansoft

Designer was acquired and installed in the lab computers. Now we have

access to the same resource the industry is currently using. This took

us out of a few-month long stagnation.

4.3 Course format change

It became evident that the initial plan of 30 modules to build is

infeasible. The format for the course will be changed keeping the main

objectives intact. They are:

- The course emphasizes the laboratory experience.

- After completing the course, every student has built a few nontrivial

RF circuits.

Throughout the semester, every student will build three circuits: an

amplifier, a VCO, and a mixer. In the VCO, the amplifier circuit will be

incorporated. In the mixer, the VCO and the amplifier circuit will be

incorporated. This way tha final circuit will become a complete

2.4GHz tuner, and the design consists of three incremental steps.

File translated from

TEX

by

TTH,

version 3.61.

On 28 Sep 2004, 11:18.