Development of Microfluidic Membrane Filtration Devices for Nanoparticle Concentration and Purification

Solvent resistant nanofiltraion (SRNF) membranes have been recently developed to purify mixtures to smaller than 2nm molecular. It is different from reverse osmosis to permeate only solvents. Each SRNF-membrane has its own molecular weight cutoff (MWCO) which is the molecular weight corresponding to a reference compound that is rejected for 90%. Nowadays commercial SRNF-membranes are developed for different kinds of materials such as polymer and ceramic. Each material property can be used to make SRNF membrane to assemble microfluidic devices. Polymer SRNF membrane can be embed in microfluidic devices. Ceramic SRNF membrane has its own properties to operate in harsh condition in as a wide pH range (2-14), resistant to most polar and non-polar solvents, and even at extremely high temperatures (~ 350ºC).

Microfluidic nanofilitration |

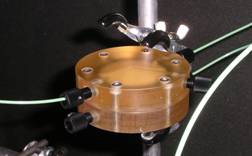

Macroscale Test Fixture |

The synthesis of nanoparticles in a microreactor is developed to get a narrow distribution of particle size in controlled condition. But the purification step is still the same method as a batch scale synthesis such as quenching in a non-polar solvent, filtration through a sintered frit, re-dissolving a solvent and re-crystallizing via solvent evaporation. These sequential steps require more solvent and time than the synthesis step. The development of a SRNF extractor for the purification of nanoparticles will be able to characterize the conditions to yield maximum products and high quality, and reduce the extra solvent and time. On line interfacing with upstream microreactors will be a step for upscaling and industrial implementation.

Reference:

Rundel, J.T., et al. Journal of Chromatography, A (2007), 1162(2), 167-174

Vandezande, Pieter, Chemical Society Reviews (2008), 37, 365-405